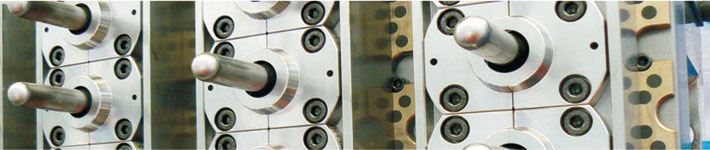

China Preform Mould Maker

Blow molding technologies

With the popularization health preservation, growing people attach importance to drink water. Then the demand of bottles is more and more large. So we need a perfect blow mould to produce ideal bottles.

PET Bottle Production Line:

Bottle blow molding processes between glass transition temperature and crystallization temperature. The temperature is always controlled within 90 centigrade and 120 centigrade. PET always exists as elastomeric state between this temperatures ranges. Then it will fast blow molding, cooled down and form a transparent bottles. In the one-step molding method, the temperature will be decided by the cooling time. So we should well link up the relationship of injection and blow.

Process of blow molding: stretch—first blow—second blow. These three actions are so short so we should completely match. The former two steps will decide the quality of the bottle. So we should adjust the starting time of stretch, speed of stretch, starting time and finish time of preblow, air pressure and airflow of preblow. If possible, it will be better to control the temperature distribution of the PET perform and temperature gradient of the outer wall and inner wall of the PET perform.

During the quick blow and cool process, induced stress in the wall of bottle will generate. For the effervescent beverage bottles, they can resist internal pressure. But for the hot filling beverage bottles, it should assure above the glass transition temperature which can help it fully unleash induced stress.

PET bottle production line always consists of much equipment:

- Preform Mould

- Preform molding system

- Bottle Mould

- Bottle blowing system

- Filling system

- Conveying system

- Downstream Packaging System

Sino Mould is professional mould, injection machine and any other equipment supplier who can provide you with economical solution about blow molding line.

Poster: Jocelyn Xie

Mail: sino1510@sinomould.com