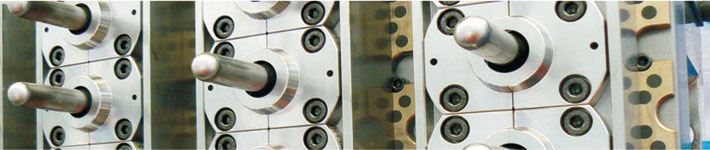

Preform mould manufacturing Service

Cap mould / Preform mould manufacturing service

SINO-PK provide services of before preform mold manufacturing services, during the cap mould or preform mould manufacturing services and after cap mould or preform mould manufacturing and delivery services. These services are covering on preform mold components, preform molds spare parts, preform molds design service, preform molds manufacturing…..

- Before cap mould / preform mould manufacturing services:

1. We tell you the preform mould or cap molds’ cavities nr. based on your information of daily or monthly production quantity. For example the preform mould cavities nr., you only need to tell us the bottle daily or monthly quantity and also tell us your machines tonnages, then we can calculate for you that how many cavities or how many sets of the preform mould or cap mold you need.

2. If you do not have ready machines in your workshop, then we help you to select the machine model nr. for you.

3. If you are the new people for PET or cap moulding, then we help you to design the workshop layout for machine, raw material treatment, water pipe, gas and electricity wire displaying. If you will produce bottle by yourselves, we also help you to selection the blow molding machine cavities and station nr….

4. We also can provide you the bottle design, due to the bottle design is the very important issue for the cost saving and bottle’s strength. For example, if you need a accurate volume bottle with less weight but stronger, then you need a perfect bottle design. After the bottle design ready, then we need a very special preform design to meet the bottle design.

5. We also can help you to calculate the production cost based on your market labor cost, power cost and raw material cost.

- During cap preform mould manufacturing services:

1. After we have got your P.O. and we started the mould manufacturing, we keep you informed for the mould status by SINO Standard Mould Tooling Schedule reports, this report will be updated by each week.

2. SINO sales team send you the mould plates or mould components pictures weekly.

3. During the mould order process and before the shipment, SINOPK keeps very often communication with your esteem company. We request your esteem company offering us as detailed as possible information: such like electricity power parameter, plastic material model nr., custom clearance requirements…and so on.

4. Preparing the mould operation manual and maintenance manual with some very important notice. These notice is also sent to you by email with very clear notifications.

- After cap /preform mould manufacturing and delivered services:

1. When the mould delivered, normally, it has 12.5% or 25% spare parts packed with the mould. It can guarantee that within couple years you do not need any spare parts shortages.

2. If you need any components from SINOPK for preform mould or cap moulds, we send out within 1 working day, because for the preform mould and cap mould, sino has standard stocking in the warehouse. If the components you need is not for preform or cap mould, then normally we need 7 working days to make it ready for delivery.

3. SINO can send engineers to over sea for machines installation and mould operating.

4. SINO offer the training to your teams for the PET preform and cap molding, also do the mould basic maintenance or repairing services.

5. SINO service team has 16 members, they are flying every week and most of them is now on the trip from Mexico to Brazil, from Brazil to Peru...