China Preform Mould Maker

Fliptop Cap Mould

- Total 0Page0Records

Flip top cap is widely used, like shampoo bottle, shower gel, toothpaste, cosmetic bottle and so on. Sino made a lot of moulds for various kinds flip top cap every year.

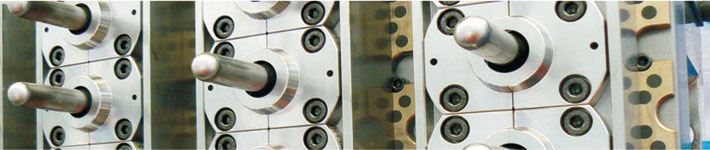

Flip top cap mould structure

Fully automatic closed inside the mould is one of the ways to realize fully automatic production of flip top. Flip top cap must be closed after molding immediately to ensure the flexible of cap bend. If customers make the mould without fully automatic closed, it will require an extra equipment to help the cap to close after molding.

Sino used to successful with 24 cav toothpaste cap mould with fully automatic closed structure and unscrewing structure. It is breakthrough in technical, because normal injection machine don’t have function to realize these two actions in one time, the machine program should be changed accordingly to realize it. We succeed it.

Flip top cap mould hot runner system:

Anole hot runner system professionally design for small volume injection hot nozzle, with the temperature controlling system. Heating elements and thermocouples are made in German.

Flip top cap mould steel

As cap mould always work under high speed and high output, so it has high requirement on mould steel quality. The steel used for cap mould should be with hardness no less than 42HRC, generally, we use S136 steel with hardness HRC 48-52 for cap moulds, we can ensure mould life for 5M shots.

Flip top cap mould tooling

We use high precision CNC tooling machine to make the moulds, to ensure the size of each part is qualified, on each part we make, there will have qualified mark and its number to identify.