China Preform Mould Maker

Home > Spray cap mould >

Spray Cap Mould

- Total 0Page0Records

Spray cap is mainly used for insecticide bottle, air refresher bottle, and cleaner bottle and so on. This kind of cap has rigid requirement on emitted dose, so it must have precision dimension control.

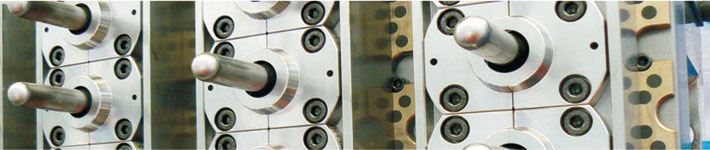

Spray cap mould structure

Sino as professional cap moulds manufacturer, it has high mentality of cap mould design, for such spray cap, we design the mould consider how to help the mould realize high speed injection and let mould with long life. Mould injection system, cooling system and ejector system are 3 main system of one mould; we optimize all of them to get high quality mould. Especially of the small spray hole.

Spray cap mould hot runner system:

Anole hot runner system professionally design for small volume injection hot nozzle, with the temperature controlling system. Heating elements and thermocouples are made in German.

Spray cap mould steel

As cap mould always work under high speed and high output, so it has high requirement on mould steel quality. The steel used for cap mould should be with hardness no less than 42HRC, generally, we use S136 steel with hardness HRC 48-52 for cap moulds, we can ensure mould life for 5M shots.

Spray cap mould tooling

We use high precision CNC tooling machine to make the moulds, to ensure the size of each part is qualified, on each part we make, there will have qualified mark and its number to identify.