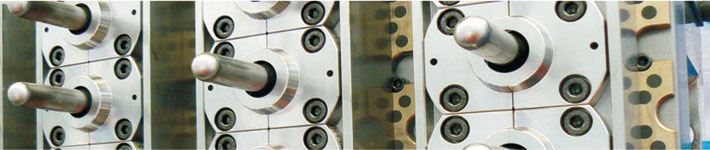

Preform molds QC

Preform molds __ quality controlling

Preform molds and cap mould quality controlling system made SINO-PK improving and developing very fast, the preform molds are very sensitive, due to preform molds and cap moulds are always multi cavities, they need very precise machining to all the plates and components, also they need very good hot runner system. Especially for , they need valve gate injection system and the valve gate injection system need very precise material sealing function, also need precise temperature controlling to keep the injection force equal and injection force balanced.

- Preform molds / Cap mould cavities, cores and screw neck…components material selection.

We have special selection on the components material, and also do different harden or surface treatments. We use Stavax S420 for cavities and cores and DIN 1. 2083 for screw necks inserts...

- Preform molds / Cap mould components machining process.

From 2008 to 2010 May, we have invested more than 7 millions USD tooling machines from Europe and Japan which are especially for Preform molds / Cap mould manufacturing. All the components of the mould will be made accordingly to our 2D prints tooling drawings, on the the drawing, there are tolerances, tooling process, material hardness…all the details. When the parts on the machines, it was measured to be sure the dimensions are meeting our tolerance. Before the components moving to assembling workshop, the QC department will make one more time measuring to be sure the dimensions are meeting the drawings’ tolerances.

- Preform molds / Cap mould’s components are interchangeable.

Due to the high precise machining and rigorous dimensions controlling, in our Preform molds / Cap mould all the same parts realized interchangeable, and for so many components which are same in different moulds, we kept them as the stocks for faster delivery time and prompt services to our customers.

- Preform molds / Cap mould injection molding speed.

We considered the preform molds running speed from the mould design, such like injection system, guiding system, ejection system and cooling system. In one cycle time, for example 28 seconds, the cooling time take 12 seconds, for this reason, we have considered to make the cooling outside of the mould by one vice cavities group, on these vice cavities, we used chilling water on it. By this way we can reduce around 10 seconds for each cycle.

- Preform molds / Cap mould security system.

We have designed the electronic eye on the Preform molds / Cap moulds to be sure that if there is some preform has not drop down, the mould will not closed. Also there is stroke switches on the mould to be sure the ejection return strokes are correct. In this way, we kept sure that the mould will be long life running.

- Preform molds / Cap mould mass production simulation.

Before the moulds shipment, we take at least 8 hours mould mass production speed running on our especial PET injection molding machine, to be sure that there will be none problems when the Preform molds / Cap moulds arrive our customer’s workshop.

- PET Preform quality:

1. Water connections consolidated at the bottom of the mold, eliminating the potential for water marks on PET preforms.

2.Variety of stack designs and surface finish options to allow each application to be optimized to meet customer’s specific needs.

3.Special programs available when tighter than industry standard dimensional and/or weight tolerances are required

4.Lowest cavity-to-cavity weight and dimensional variation as a result of best-in-class manufacturing machines and processes