China Preform Mould Maker

High Output cap molding

Cap molding requires high speed production special for common water bottle cap and juice bottle, as it has high demands on output. How to reach high efficiency cap molding? Sinocan offer you cap molding line with high output closure molding solution.

To reach a high speed cap molding, the injection molding machine and cap mould design is very important.

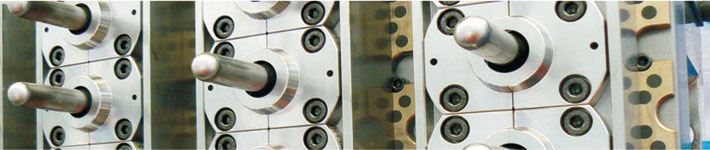

Cap mould design

1. Cooling system design

The cooling must efficiency; it is one most important factor for mould life after long time running. The cooling channel should aside the molding surface as near as possible and size of cooling channel hole also should as large as possible to ensure enough cooling.

2. Ejector system design.

Ejector is one of the main action during molding, cap mould some with direct ejector system, some with unscrewing ejector system, direct ejector can save a lot of time, but the cap thread must not so deep that we can use direct ejector.

Injection molding machine

Injection molding machine must have good ability of precision controlling, and the injection must be very good. Only with good support of the injection molding machine, the mould can run fast and reach a high output.

If you want to buy any cap molds and reach high output, feel free to contact me.

Posted By Elaine

E-mail: quotation@sinomould.com