Injection Mould industry development tendency

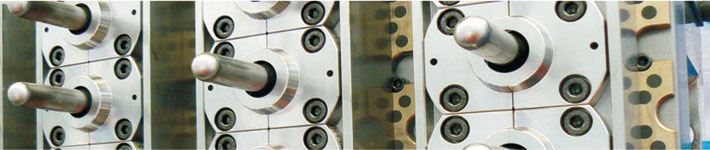

Injection Mould industry is booming for many years all over the world, especially in China. How is the mould industry going now?

First, injection moulds become bigger and bigger. It is because the molding parts are becoming bigger and bigger, for small parts, the mould will be with multi cavities, so the injection mould size will be bigger and bigger.

Second, injection moulds dimension will be more and more precision. A decade ago, tolerance of 0.005mm is very precise as to mould dimension, now the tolerance can be controller within 0.002 to 0.003, in near future 0.001 can be realized, I believe. So the mould tooling machine will be better and better.

Third, the application of hot runner in moulds will be occupy for more percentage. As hot runner can improve product quality and production efficiency, also it can save a lot of material, so it developed rapidly, in abroad, the hot runner already occupy more than 50%, some already reach 80%, now in china, the percentage of hot runner is about 20% -30%, I believe it will be more and more in near future.

Fourth, as the injection molding process improve day after day, new technology like gas assistant injection and other technology become more and more popular, it increases the demands on mould, especially the mould steel quality, must with good hardness.

Fifth, high speed injection. Nowadays, production efficiency is very important to a maker, efficiency just mean profit, so high speed injection will be one main tendency of the mould development.

Making moulds must consider in customer side, how to make maximum profit with smallest cost, to follow the tendency or lead the tendency of the mould development will help you success in mould industry. Sino Mould is one of the wise mould manufacturers, if you have any inquiry, feel free to contact me.

Posted by Elaine

E-mail: service@sinogroupe.com