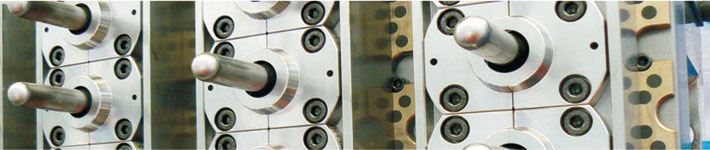

PET bottle molding type

To make PET bottle, in current market, there are various ways to make, mainly have 3 different types:

The 2-stage process: it requires aninjection molding machine to make the preform, and then a stetch blow molding machine to make the bottle. Machines and moulds with many cavities have been developed for high production rates with this "two-stage process", making it the process of choice for high output applications such as carbonated soft drinks and mineral water bottling.

The 1-stage process: for this kind process, it only takes one machine to make the preform and bottle together, now only have several big and good company can do this and the machine cost is very high, so it is not widely used in the market.One-stage machines are well suited to low production rated and to bottles with asymmetrical shapes or with wide neck openings. The one-stage process is less energy intensive than the two-stage process because it eliminates the need for complete cooling of the preforms and later their reheating for stretch-blowing.

The 1½-stage process: Sometimes also called the integrated process, this is a variant of the one-stage process, where one machine is used for injection of preforms and stretch-blowing of containers, but the preforms are not transferred directly from the injection to the blowing station. Instead they are removed from the injection mould and placed on a transfer chain, which passes them first through an oven for reheating and then to the blow moulds for stretch blowing. In this integrated process, the number of blow mould cavities is smaller than the number of injection mould cavities, taking advantage of the faster blowing cycle compared to the injection cycle (unlike the 1-stage process where the number of injection and blow cavities are the same).

Actually, in nowadays, two stage process molding is more popular, we can offer a complete production from PET preform mould, PET injection machine to blow mould and blow machine,

If you have any project for bottle under going, feel free to send your inquiry to us.

Posted By Elaine

E-mail: service@sinogroupe.com