China Preform Mould Maker

Preform moulds tooling

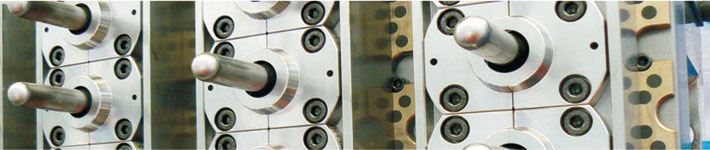

Preform moulds tooling has high requirement on precision; it is very important to final preform sample, control the preform wall thickness and weight.

Preform mould main parts: preform mould core, cavity and neck ring insert, mould plates.

The main tooling process of preform mould is lathe and milling.

Sino Mould invest about 5 Million RMB in 2012 to purchase the high precision tooling equipment to ensure the mould quality. We have 3 sets high speed and high precision lathe machine and 6 sets high speed and high precision milling machines. These machines can control the tooling tolerance within 0.03mm. So it increases our mould tooling quality by a big step.

If you have any project for PET preform mould, feel free to contact with us, we have full confidence to offer you high quality mould with a very good price.

Posted by Elaine

E-mail: service@sinogroupe.com

Preform mould main parts: preform mould core, cavity and neck ring insert, mould plates.

The main tooling process of preform mould is lathe and milling.

Sino Mould invest about 5 Million RMB in 2012 to purchase the high precision tooling equipment to ensure the mould quality. We have 3 sets high speed and high precision lathe machine and 6 sets high speed and high precision milling machines. These machines can control the tooling tolerance within 0.03mm. So it increases our mould tooling quality by a big step.

If you have any project for PET preform mould, feel free to contact with us, we have full confidence to offer you high quality mould with a very good price.

Posted by Elaine

E-mail: service@sinogroupe.com