China Preform Mould Maker

Quality control of injection mould

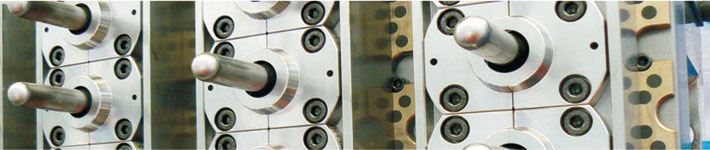

SINO Mould focus on the high quality and the precision of injection mould. Due to the high quality and high lifetime of our mould, SINO brand is famous all over the world.

The first key point of our SINO MOULD is to control the quality of the plastic design and mould structure improvement. This improvement not only for tooling on the work, tooling speed and delivery time, but can also avoid many unnecessary jobs before mould test.

SINO has more than 50 designers and engineers for plastic part, mould design and analysis. All software: UG, PRO-E, CATIAA and AUTO CAD, Following analysis plastic design mould structure tooling on the work and tooling tolerance. Designers output the 2D tooling drawing for QC and tooling machine are ready to follow.

The second key point of QC control is that each tooling elements by test machining in precise quality control. SINO tooling centre achieves in high precise tooling dimension as well as inspection in bridge coordinate measuring machine and other high precision inspection equipment.

QC department can detect and solve problems to prevent errors in production processes. On the other hand, QC reports how project manage would inspection material, tooling management assembling processes as well as mould test. No handwork allowed on the parting surfaces and standard components of mould.

The first key point of our SINO MOULD is to control the quality of the plastic design and mould structure improvement. This improvement not only for tooling on the work, tooling speed and delivery time, but can also avoid many unnecessary jobs before mould test.

SINO has more than 50 designers and engineers for plastic part, mould design and analysis. All software: UG, PRO-E, CATIAA and AUTO CAD, Following analysis plastic design mould structure tooling on the work and tooling tolerance. Designers output the 2D tooling drawing for QC and tooling machine are ready to follow.

The second key point of QC control is that each tooling elements by test machining in precise quality control. SINO tooling centre achieves in high precise tooling dimension as well as inspection in bridge coordinate measuring machine and other high precision inspection equipment.

QC department can detect and solve problems to prevent errors in production processes. On the other hand, QC reports how project manage would inspection material, tooling management assembling processes as well as mould test. No handwork allowed on the parting surfaces and standard components of mould.

SINO QC had developed the various maturing inspection reports flow tolerance suitable for each different molding inspection.

The third key point is mass production simulation running of each mould which is the feature of SINO mould .SINO has more than 20 sets injection molding machines from DKM 50 ton to DKM 1800 ton which are used for T1 trial and simulation running before shipping.

The third key point is mass production simulation running of each mould which is the feature of SINO mould .SINO has more than 20 sets injection molding machines from DKM 50 ton to DKM 1800 ton which are used for T1 trial and simulation running before shipping.

Rebecca

skype:dakumar-06

Msn: dakumar-06@hotmail.com

e-mail: service15@sinomould.com