China Preform Mould Maker

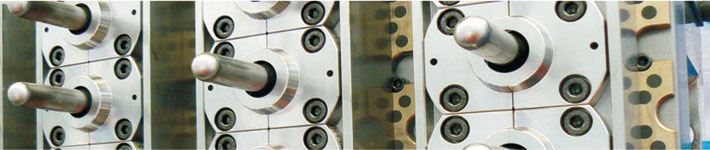

Cap mould plastic injection

As we know, the size of cap is small and it always put into mass production. For the thread of the mould, it can be divided into external thread and internal thread. In general, internal threaad can be formed by threaded core and external thread can be formed by thread ring. Thanks to the particularity of the thread, the mould structure of thread and demould methods are different.

For the internal thread of the cap, it can designed as segmented threads if permitted. As for the complete internal thread, the main injection moulding technology such as:

- We can choose forced demolding method, but it will be work with the permission of mould structure. And we also should use plastic with good flexibility.

- We can make thread core as a movable insert and the manually strip outside the mould. Although the mould structure is more simple, the production efficiency is low, labor intensity is large and it is also hard to realize automatedoperation.

- We can adopt the rotating mechanism to realize automatic thread demoulding. It have many advantages, such as high production efficient, low labor intensity, automatedoperation and mass production.

Welcome to Chinese professional mould manufacturer——Sino Mould. We have much experience in this field. If you are interested in our company, please don’t hesitate to contact us for cap molds and plastic injection molding technology.

Poster: Jocelyn Xie

Mail: sino1510@sinomould.com