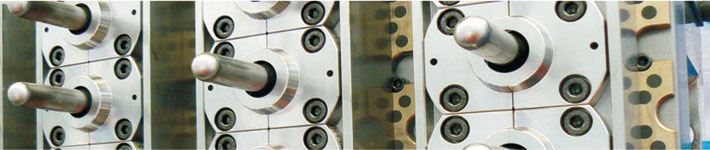

China Preform Mould Maker

solution of PET injection molding

PET container has become globally wide use package material and container. And it has been widely used in many fields, such as food, drink, wine, cosmetic, daily use, industrial supplies, agricultural supplies and so on. And a good PET container will depend on the molds which contribute to enhance the quality of the PET container.

Generally speaking, the molding method of PET bottle can be divided into injection stretch blow molding and stretch blow molding.

- injection stretch blow molding method: The method is on the same machine where products will finish all processes. Firstly, the molten PET preform, and then it will process stretch blow molding on the hollow mould. It is always called one step due to the molding of PET preform and stretch blow molding are on the same machine. Moreover, the PET preform has processed stretch blow by using afterheat when it hasn’t cooled. So it is also called hot preform method.

- Stretch blow molding method: Firstly, the machine shoot the PET preform, secondly, the cooled PET preform will be heated on the stretch blow molding machine and then process stretch on the hollow mould. It is always called two steps due to the PET preform are procesed on the injection molding machine and blowing machine. Moreover, after the PET preform has been cooled, it will be heated and stretchly blowed. So the method is also called cool preform method.

The production processes of stretch blow molding are as follows:

Sino Mould is a professional blowing molds manufacturer and supplier in China. We have much experience in this field. If you are interested in our company, please don’t hesitate to contact us for blowing molds and blow molding solutions.

Poster: Jocelyn

Mail: sino1510@sinomould.com

|

|

|

|

|

|

|

|