China Preform Mould Maker

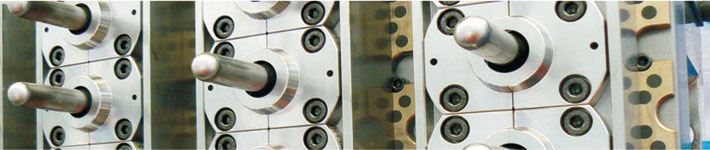

Cap/Closure Injection mold custom

To Custom injection mold of cap/closure from China market.

Cap/Closure mold has high requirement on mold precision and the fitting between cap and bottle neck is very important.

How to custom a good cap/Closure injection mold? Of course the mold maker is very important, while the active cooperation of buyer is the same import.

During design stage:

We must consider all aspects during design, because after confirm the design and start manufacture, it is not easy and not good to change any more.

Customer must offer every detail of the cap to help the maker to make the design, especially to offer the bottle neck, if this cap needs to be fit to various bottle, customer must offer all the bottles.

The shrinkage of the material is another important factor during design, different shrinkage will lead to different dimension result, so before design, the shrinkage must make clear.

During manufacture

After both the customer and maker confirm the product design and mould design, then it is the manufacture.

The mould maker must control well of the mould tooling dimension. Each step should have report of the tooling dimension, if we find any parts dimension beyond the tolerance, we should re-tooling it or make the new one.

Finally for the assembling and mold testing:

Mould assembling must do very carefully; make sure every part press very well. After assemble the mould, for the mould testing, we must in the condition very similar to the customer’s factory condition, it can make sure there will no problem during real production, so at least 2 hour simulation production is necessary.

If you have any inquiry about bottle cap/ Closure, feel free to send me your inquiry.

Posted by Elaine

E-mail: quotation@sinomould.com

Cap/Closure mold has high requirement on mold precision and the fitting between cap and bottle neck is very important.

How to custom a good cap/Closure injection mold? Of course the mold maker is very important, while the active cooperation of buyer is the same import.

During design stage:

We must consider all aspects during design, because after confirm the design and start manufacture, it is not easy and not good to change any more.

Customer must offer every detail of the cap to help the maker to make the design, especially to offer the bottle neck, if this cap needs to be fit to various bottle, customer must offer all the bottles.

The shrinkage of the material is another important factor during design, different shrinkage will lead to different dimension result, so before design, the shrinkage must make clear.

During manufacture

After both the customer and maker confirm the product design and mould design, then it is the manufacture.

The mould maker must control well of the mould tooling dimension. Each step should have report of the tooling dimension, if we find any parts dimension beyond the tolerance, we should re-tooling it or make the new one.

Finally for the assembling and mold testing:

Mould assembling must do very carefully; make sure every part press very well. After assemble the mould, for the mould testing, we must in the condition very similar to the customer’s factory condition, it can make sure there will no problem during real production, so at least 2 hour simulation production is necessary.

If you have any inquiry about bottle cap/ Closure, feel free to send me your inquiry.

Posted by Elaine

E-mail: quotation@sinomould.com