China Preform Mould Maker

How to ensure High quality preform mould?

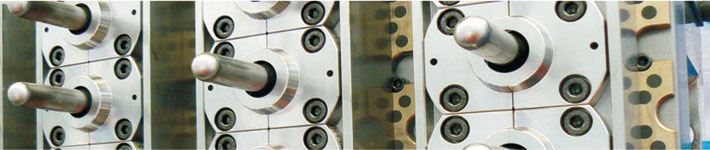

PET preform mould mainly consist of core insert, cavity insert, neck insert and all the plates. Customer always have high requirement on preform weight and size, especially neck size, so tooling precision is especially important. Sino Mold bought several imported tooling CNC machine especially for PET preform mould, these machine can control the tolerance within 0.05mm. on the other hand, it ensure there is no problem to replace the parts with spare parts.

Besides the tooling equipment, we have done improve on our cooling system design, as we know, PET preform mould always with multi cavities, during production, it generates a lot of heater, so the cooling system to a preform mould is extremely important to ensure the mould life. For common preform mould, the cooling channel diameter is 8mm or 10mm maximum, while SINO customize a water connector with size at least 30mm, so more water can cycle in the mould that ensures good cooling of the mould.

If you are interested to buy PET preform mould, pls don’t hesitate to contact us, we can offer you high quality preform mould.

Posted by Elaine

E-mail: service@sinogroupe.com