China Preform Mould Maker

Offer PET perform turnkey production line

Recently, so many customers ask for PET perform turnkey production line, here I’d introduce some detail of the items which we offer for reference.

Generally, one production line includes plastic mould, injection machine, and auxiliary equipment.

For PET preform production line, the equipment list as follow:

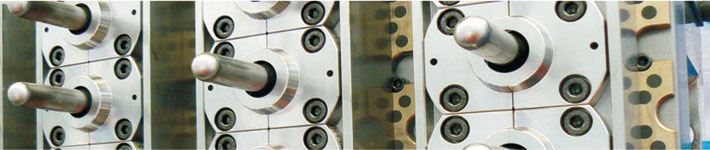

1. Hot runner PET perform Mould (with mould temperature controller)

2. PET special injection molding machine

3. Air compressor, it’s better to use screw type air compressor, it is better for injection machine

4. Three in one compact dryer (material feeding, dehumidifying, drying)

5. Water Chiller or Air Chiller, it depends on customer’s factory situation, if water is sufficient in your country, water chiller will be better, but at the same time, your factory should have water tower.

6. Water Tower. If you use water chiller, it is necessary to equip with water tower

7. Mould dehumidifier (optional). If the weather is very humid in your country, then your mould needs to be dehumidified as well.

Above list is just the simple list for reference, the detail solution should be according to customer real situation,

the customer should offer the supplier information as follow:

1. Preform information, like neck size, weight, it’s better with a drawing

2. Bottle drawing (if possible), it will help preform supplier to help you check whether the preform design is good for blow or not.

3. Output quantity you want to reach. It is very important, because it will decide which machine size is suitable for you, and how many cavities does the mould needs.

If you have any inquiry about preform production line, feel free to send your inquiry to me.

Posted by Elaine

E-mail: service@sinogroupe.com

Generally, one production line includes plastic mould, injection machine, and auxiliary equipment.

For PET preform production line, the equipment list as follow:

1. Hot runner PET perform Mould (with mould temperature controller)

2. PET special injection molding machine

3. Air compressor, it’s better to use screw type air compressor, it is better for injection machine

4. Three in one compact dryer (material feeding, dehumidifying, drying)

5. Water Chiller or Air Chiller, it depends on customer’s factory situation, if water is sufficient in your country, water chiller will be better, but at the same time, your factory should have water tower.

6. Water Tower. If you use water chiller, it is necessary to equip with water tower

7. Mould dehumidifier (optional). If the weather is very humid in your country, then your mould needs to be dehumidified as well.

Above list is just the simple list for reference, the detail solution should be according to customer real situation,

the customer should offer the supplier information as follow:

1. Preform information, like neck size, weight, it’s better with a drawing

2. Bottle drawing (if possible), it will help preform supplier to help you check whether the preform design is good for blow or not.

3. Output quantity you want to reach. It is very important, because it will decide which machine size is suitable for you, and how many cavities does the mould needs.

If you have any inquiry about preform production line, feel free to send your inquiry to me.

Posted by Elaine

E-mail: service@sinogroupe.com