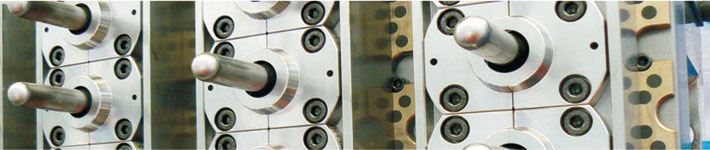

China Preform Mould Maker

Bottle cap molds for sale

With the increase of demand for plastic bottle caps, the quality requirements of caps are increasingly high. So it needs high level of design and manufacture of the moulds.

Because of the many factors,such as the overall dimension of mould and machining operation. The gate of the mould would adopt side gate which is also called edge gate. In general, side gate is always set up at the parting surface of the mould and feedstock from the side of the mould. It can conveniently adjust the gate type which is always adopting rectangular section.

When it is cooled, plastic parts will be wrapped in core because of systole action. From the view point of demoulding plastic part, should be beneficial to detain it on the male die. It not only contributes to demould, but also will not influence the quality, appearance of plastic parts and dimensional precision. Runner system generally consists of four parts, including main runner, branch runner, gate and slug well.

The design of runner system should assure the smooth flow of the plastic molten mass, flow path should be short which prevent cores deformation. And the design of slug well should be reasonable so that reduce the consumption of plastic.

The section of plastic parts should be thin. Bottle cap is unfit for detrusion by using ejector pin, stripper plate will be better. On the base of protecting the appearance of plastic products, branch runner should adopt round section, and sprue bushing should be set up on the matrix plate.

Sino mould is a professional bottle cap molds maker and supplier in China. We have accumulated much experience in this field. We have cooperated with many companies domestic and overseas. And we have gained much good reputation from our clients. If you want to know more information about bottle cap molds, please feel free to contact me.

Poster: Jocelyn Xie

Mail: sino1510@sinomould.com