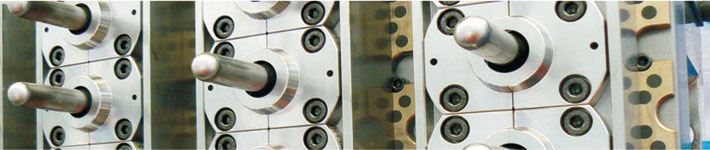

China Preform Mould Maker

Cap mould moulding technology

As different kinds of cap moulds enjoy respective functions, cap mould is different from other cap mould in structure and design. Thus, cap mould injection moulding will be more important and play a key role in the whole process.

As a small plastic product, cap always adopt multi-cavity mould. Because of big dosage, if permits, more cavities will be good. If cap has internal thread and Anti-counterfeiting circle, we should adopt forced demolding. So mould will be good to be designed as three plate mould. After finishing injection, cap will get out from the fixed mold along with the internal thread cores and then be forcedly demolded. When adopt forced demolding, the cap have to overcome two part resistance of internal thread and water fender. Such being the case, we can adopt twice demolding to avoid the big resistance. Firstly, we need to get the internal threads off, and then get the water fender off. Therefore, the cavity of the mould is designed as compound three layer structure. The outer layer is thread core, the middle layer is water fender core, and the innermost layer is ejector pin. Inner core is set up in the moving plate so that realize twice demolding.

Welcome to Chinese professional mould manufacturer——Sino Mould. We have much experience in this field. If you are interested in cap mould or any other product, please don’t hesitate to contact me for molds and plastic molding service.

Poster: Jocelyn Xie