China Preform Mould Maker

Many boxes’ wall is thin. Such as food container,bucket and so on. This kind of box mould standard is higher than generally box mould.

To make PET bottle, in current market, there are various ways to make, mainly have 3 different types:The 2-stage process,The 1-stage process,The 1½-stage process

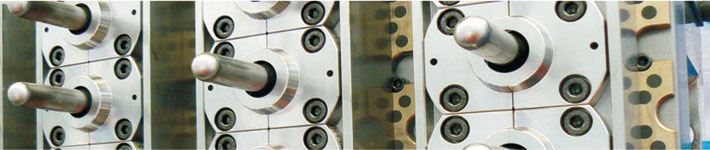

PET preform mould still highly required in market. PET preform mould become with more and more cavities to meet high requirement on output. SinoPK as a professional PET preform mould manufacture, PET preform mould maker,

Preform mould production line is the hot item of the Africa ,South America, India etc,Sino Holdings Group is involve in this field to make the perfect perform mould for customers and offer the whole solution. We are the

SINO-PK the provider for plastic injection syringe whole line solution.

For your whole line plastic injection syringe molding line we can offer you:

1. Syringe injection moulds: Barrel mould, Plunger mould, Gasket moul

Cap mould dived into toothpaste cover, bottle cap,cosmetics bottle cap,bucket cap, dustbin cap and so on.

The cap mould’s feature usually be multi cavity.For example. Toothpaste cover mould, 16 cavities, 24 cavities,32 cavities and 48 cavities. And some kind of cap should fip when open. So the mould with automatic flip syst

Preform mould from Sino-pk who is a subsidiary of Sino Holdings,with high precision dimension,high quality.

Cap mould with different type from Sino-pk is famous in China.

Cap mould ejection system :different cap with different ejection system.

Preform mold from Sino-PK ,a subsidiary of Sino-Holdings,specialized in many kind of preform mould.